Chongqing Beiyi Automobile Co., Ltd. is located in Chongqing Luohuang Industrial Park, China's motorcycle production base. It is also the manufacturer of Dayang tricycle, an international first-line brand.

Dayang has a brand value of 50billion yuan, strict quality standards, large production scale and strong personnel quality. As a national first-class motorcycle announcement catalogue enterprise, the state has a strict motorcycle access system. In 2012, there were only 15 enterprises in Chongqing that passed the national motorcycle access. We are the only enterprise specializing in the production of three wheeled motorcycles.

Our factory covers an area of 100000 square meters. The frame car is equivalent to 2 football fields, the car workshop is equivalent to 8 football fields, the paint workshop is equivalent to 6 football fields, and the assembly workshop is equivalent to 16 football fields. Self made frame, carriage, cab and other products, three line motorcycle assembly line, the factory has more than 200 sets of intelligent production equipment, such as frame keel forming equipment, frame welding equipment, carriage forming rolling mill, robot, hydraulic press, stamping machine, carriage welding equipment, vehicle assembly line, cab welding equipment

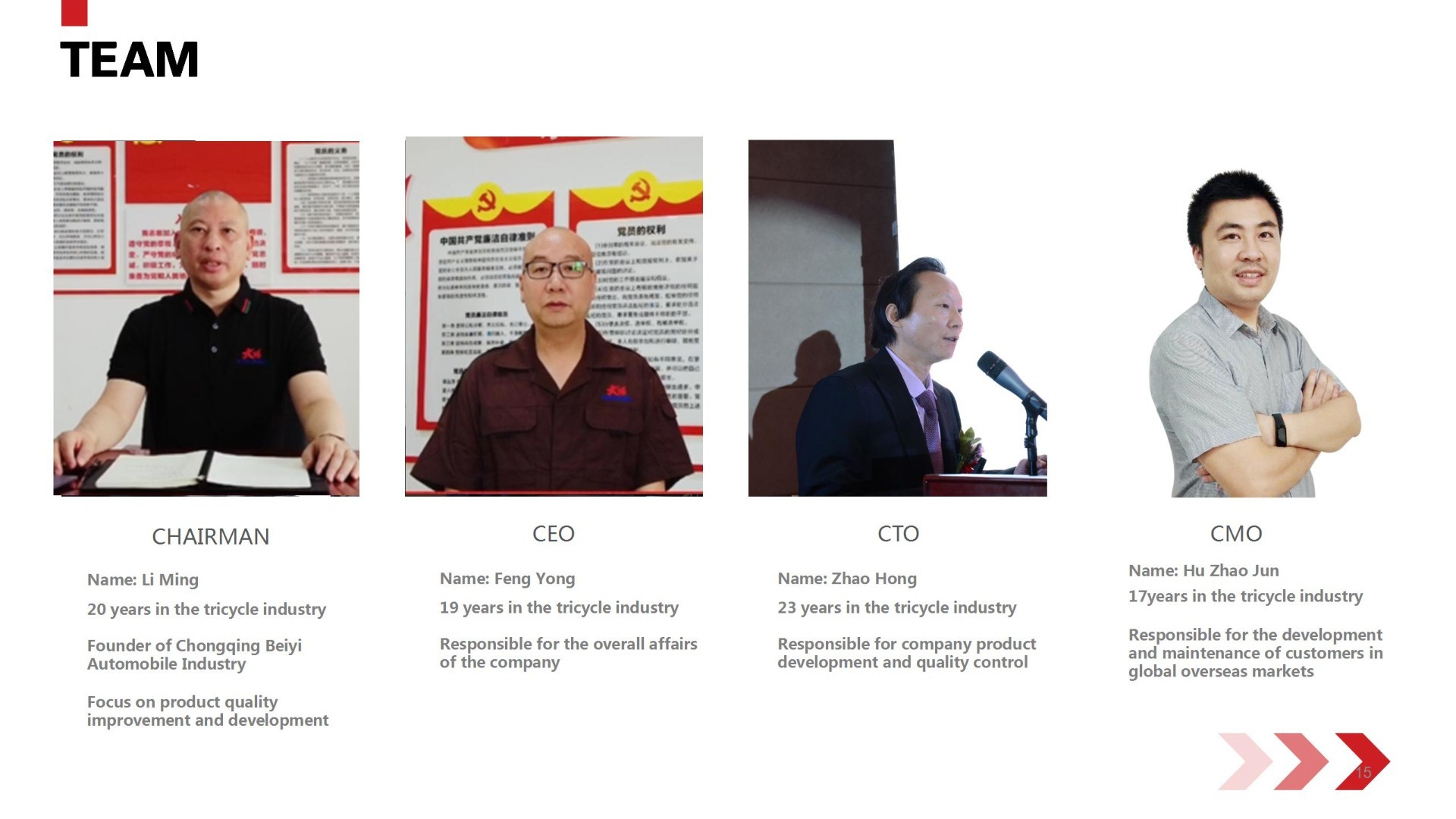

We specialize in the production of fuel electric tricycles. Only by focusing can we be professional. Unlike other companies, the company only specializes in producing three wheeled motorcycles, focusing on chassis stability, driving comfort, cargo carrying capacity, production consistency, etc. We have more than 60 outstanding engineers in the industry. As we all know, only outstanding talents can design excellent products. Our chief technical engineer majored in automobile, graduated from Beijing University of technology, designed three wheeled motorcycles with automobile technology, and has a number of national patented inventions. Our technical team is all from the motorcycle industry, with many years of experience, graduated from various academies of science, with advanced ideas and pragmatic team.

The company has comprehensive information management, such as information management for internal orders, information management for packaging and warehousing, information management for export and shipping, information management for financial accounting, information management for marketing, etc.

Our company has 1200 global customers, 870 Chinese customers, 330 foreign customers and 800 high-quality supplier enterprises. In 2021, Chongqing ranked first in the sales of three wheeled motorcycles

Quantification:

1. the annual sales growth rate of Dayang dealers is 30%-300%

2. the after-sales cost of Dayang dealers is reduced by more than 70%

3. customer satisfaction increased by more than 90%

4. the market promotion ability has been greatly improved

5. as the sales volume of dealers increases, they also have more time to sell

Scarcity:

1. for customers, we also have our own selection criteria. We choose customers who understand openness, have wisdom, and have the ability to explore the market and love their own business

2. during production, we have a production limit every month. When a certain quantity is reached, we will stop making production plans to ensure the quality of products

3. we promise to make every effort to provide customers with high-quality goods

4. if there is a chance to cooperate with customers, we will try our best to help customers improve sales

Production:

1. material and process: we will select 5-10 products that meet our standards from 100 steel products. As for other material suppliers, they will supply other second and third tier brands. Only those that meet our thickness, size and materials can pass our screening, so our selection rate is 5%-10% And our frame production line consists of 18 processes

2. we also use pneumatic fixture in production process to ensure stronger welding strength and better consistency. Tooling production refers to automobile standards and has obtained a number of patents 360 reverse tooling is used to weld the frame, so as to reduce welding leakage

3. carriage welding: 90% of carriage welding is made by CNC robot welding, with better quality and more flat and beautiful welding points

4. 3million yuan was invested to establish a shot blasting workshop to ensure that there are no bumps before baking paint, and the surface of the painted frame and carriage is flat and smooth