РRОDUСТІОN LІNЕ

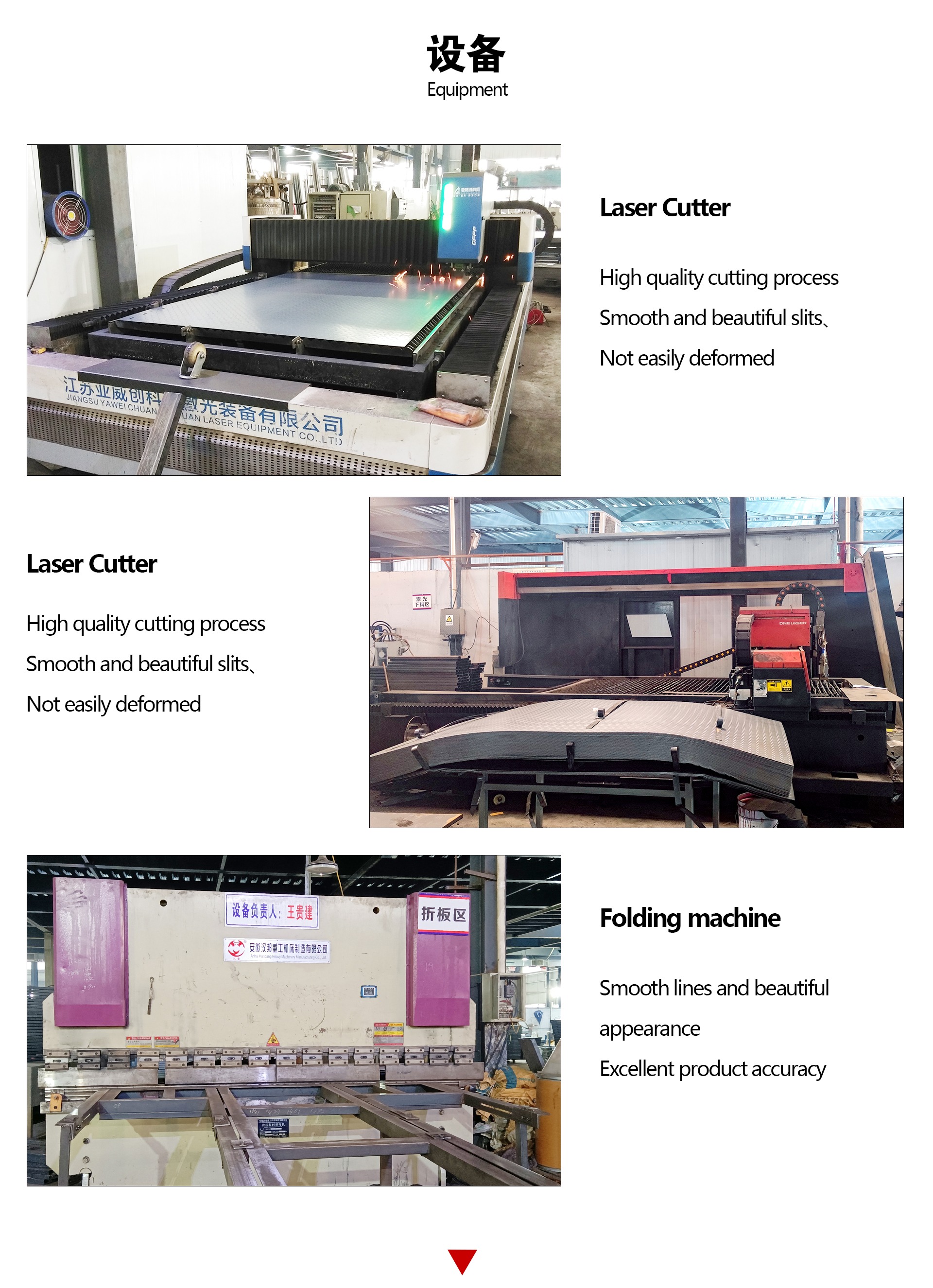

All production lines are brand- new intelligentequipment, employees are serious, careful and responsible, and comprehensive 6s management, toachieve excellence and quality first.There are a total of 185 sets of power generation equipment testing equipment in the cab workshop. Totalequipment value: 9 million sets. Annual production capacity is 500,000 sets of carriages. More than 40 setsof patented tooling equipment, valued at 3.8 million

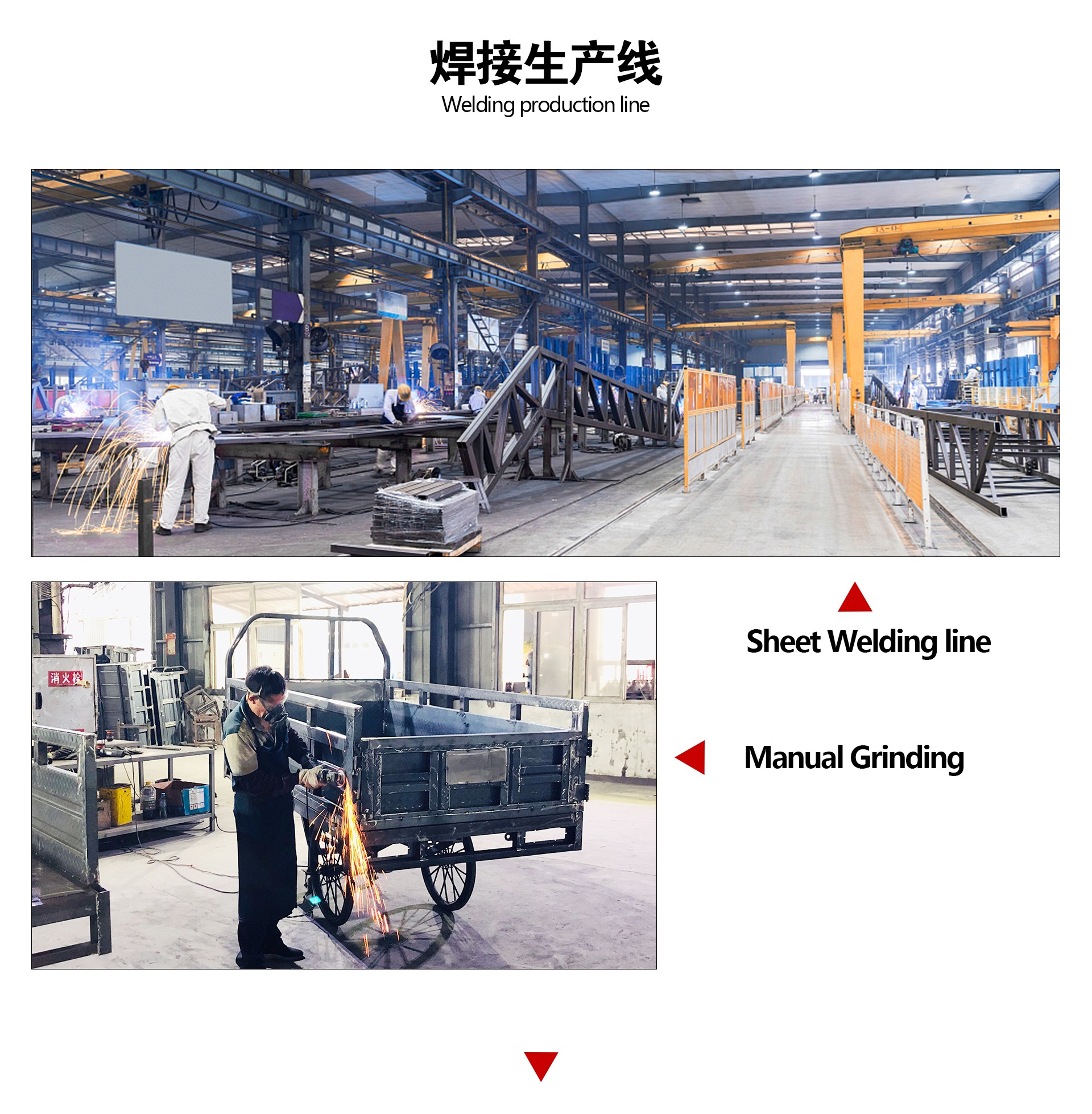

WHAT IS THE WELDING PROCESS

Cutting (some places are divided into cutting, shaping, shearing, etc.) - - assembly (includingbasic welding assembly, sheet metal production) - r product welding (this kind of welding islayered, and in many cases it must be alternated with the assembly process Several times)- post-weld treatment (including post- -weld heat treatment, failure, cleaning, etc.). This isjust a rough process, and the specific situation needs to be analyzed in detail.

WHATS A STAMPING SHOP?

Stamping is a method of forming parts with required shape and size by applying externalforce on sheet, strip, tube and profile to produce plastic deformation or separation by pressand die. Stamping and forging belong to plastic processing (or pressure processing) , collectively known as forging. The stamping stock is mainly hot-rolled and cold-rolled steel plateand strip. In the world, 60 ~ 70% of the steel is plate, most of which is finished by stamping.Automobile Body, Chassis, fuel tank, radiator plate, boiler drum, container shell, motor,electrical appliances, such as iron core silicon steel sheet are stamping processing.

WHAT IS THE COATING PROCESS

The coating production line is mainly composed of a pre-treatment electrophoresis linelelectrophoretic paint is the earliest water-based paint developed. Its main characteristicsare high coating efficiency, economic safety, low pollution, and fully automated manage-ment.Pretreatment is required before coating electrophoretic paint I, sealed bottom coatingline,intermediate coating line, top coating line, finishing line and its drying system.The whole line of the coating production line workpiece conveying system adopts a mechanizedconveying method that combines aerial suspension and ground skid. It runs smoothly,quickly and conveniently. It adopts PLC controllable programming. According to the actualrequirements of the production process, it is programmed to control-implement fieldbuscenter monitoring and partition Automatically realize the transfer operation.